|

Olamef USA, Inc.

HOME

ABOUT US

PRODUCTS INDEX

DEPANELERS

AXIAL MACHINES

RADIAL MACHINES

TRANSISTORS

IC's

ACCESSORIES

ECONOMY LINE

TAPED PARTS FEEDERS

& SPECIAL MACHINES

HAND TOOLS

COUNTERS

PIN HEADER CUTTER

FASTOR CUT MACHINE

FLAT CABLE SEPARATOR

PARTS LISTS

CATALOGS

DOCUMENTS & FORMS

NEWS

CLEARANCE

CONTACT US

SE HABLA ESPAÑOL

USA Toll Free

1-877- O L A M E F 6

+1 760

930 9206

E-mail us

|

|

Index

|

Accessories

|

Economy Machines

|

Counters

|

PCB Depanelers

|

Terminal

Machine

|

Pin Machine

|

Hand Tools

|

BGA Reballer

|

Feeders

& Special Machines

|

Flat Cable Separator

|

Parts Lists

Taped Component Feeders & Special Machines

Designed and Manufactured

for Special

Applications and for Integration

If you have a special application you need our help with, please

contact us

SP Line

machines

PDF

Information

SP Line

machines

PDF

Information

SP Line of Special Machines

Custom Pneumatic Component Feeders for Taped

Parts

MACHINES DESIGNED AND MANUFACTURED TO INTEGRATE

TO CUSTOMER’S

SPECIFIC INSTRUMENTATION

|

Olamef’s knowledge and experience manufacturing forming machines

are applied when designing this new line of equipment. This new

line helps to eliminate manually forming and inserting through

hole components thus

reducing labor costs and down

time.

Components are processed without nicking or cracking the leads.

The SP machines cut, bend and form components placing them in a

position where

they can be picked up by an automatic system to complete an

assembly cycle or

dropping them into a bin or presenting them to an operator.

Weight, dimension and volume of feeders vary on each individual

unit and depend

greatly on the customer’s requirements.

The

same SP machines can be provided fully automatic and self

standing (/A versions)

|

Following are some examples of SP Machines:

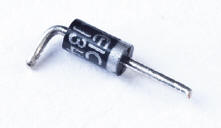

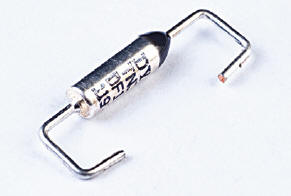

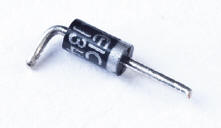

AXIAL COMPONENTS

|

|

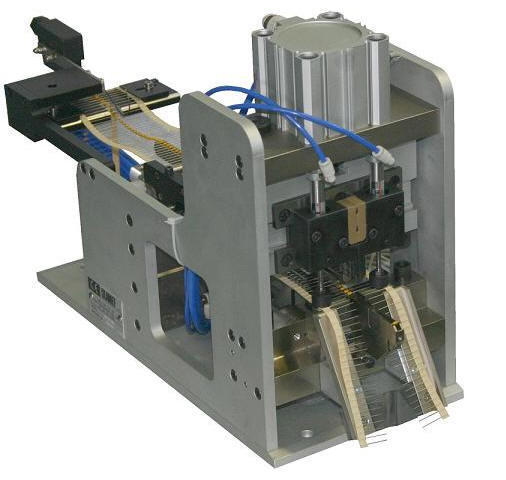

SP22

Taped Axial Components Feeder

Special pneumatic machine/feeder specially designed to customer's on

specific requirements customer to cut, bend and form taped axial components.

The tape feed occurs on a horizontal axis.

Components are individually and vertically operated

from top to bottom, the leads of the component are held on the sides of the

body during the cut, this way all risks of damage are avoided.

|

This machine/feeder is supplied without electrical, electronic or pneumatic

systems and it is mechanically operating. Then it can be integrated to an

automatic placement system.

The machine productivity is

1,200 parts per hour.

The SP22 machine has been developed for many

applications.

Following are a few examples:

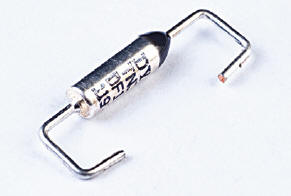

SP 22.05

CUT BEND

AND SWAGE LEADS |

|

|

SP 22.08

CUT AND 90°

BEND |

|

|

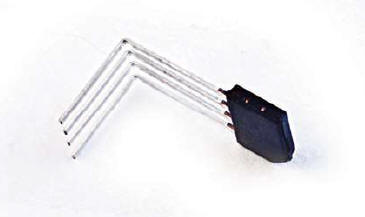

SP 22.17

CUT AND DOUBLE BEND |

|

|

SP 22.21

CUT AND

BEND FOR VERTICAL MOUNT |

|

|

SP 22.25

CUT, BEND

AND FORM |

|

|

|

|

|

|

SP22.06

Pneumatic Step by Step Feeder to cut

metal

taped terminals.

|

|

|

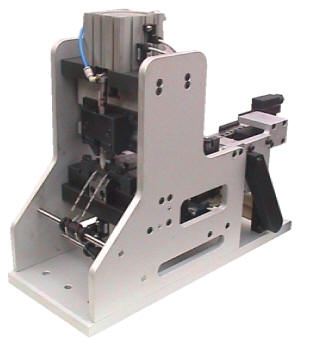

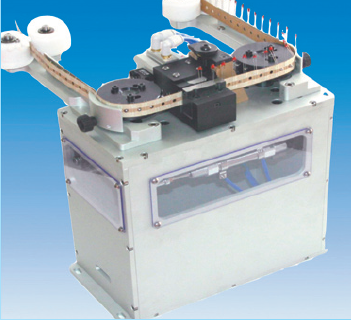

TP7

Automatic Cutting, Bending and Forming machine for

Axial taped components

If what you need is a

fully automatic self-standing machine (complete with

electronics and pneumatic systems) we can offer you

the TP7 machine.

The TP7 is a

special automatic machine designed to cut, bend and

form axial taped components to customer's

specifications.

The TP7 uses the mechanical design of the SP

machines with the addition of a PLC.

The tape feeds horizontally; each component is held

securely by holding the leads before they are cut

and during the forming operations to prevent any

possible damage to the components

|

The machine

productivity is 1,200 parts per hour.

The TP7 machine has been developed for many

applications.

Following are a few examples:

48.OL01

CUT AND 90°

BEND AND FLATTEN LEADS |

|

|

48.OL02.01

CUT AND 90°

BEND WITH KINK INWARDS |

|

|

48.OL02.04

CUT AND DOUBLE "C" BEND |

|

|

48.OL02.06

CUT, 90°

BEND AND“SEAGULL WINGS” FORM |

|

|

48.OL02.11

CUT AND ONE

SIDE 90° BEND |

|

|

48.OL02.18

CUT AND

LOOP FORM |

|

|

|

|

|

SP36

Loose Components Preforming Machines

The SP36 pneumatic machines are

designed for axial or radial loose components to be fed manually,

one at a time.

The machine’s die assembly is designed to quickly reach the forms

requested by the customer. It simplifies and speeds up

the performing process reducing

the number of steps to one single operation.

The

machine productivity is 700 parts per hour.

|

|

SP36.03

AXIAL LOOSE

COMPONENTS FORMING |

|

|

SP36.01

SPECIAL

COMPONENTS CUTTING AND FORMING |

|

|

|

|

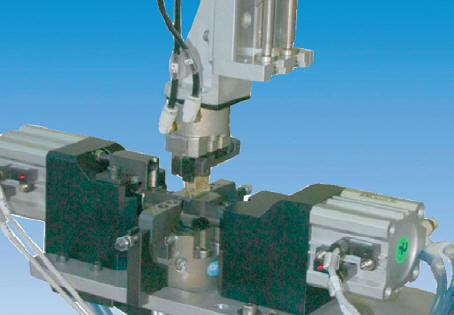

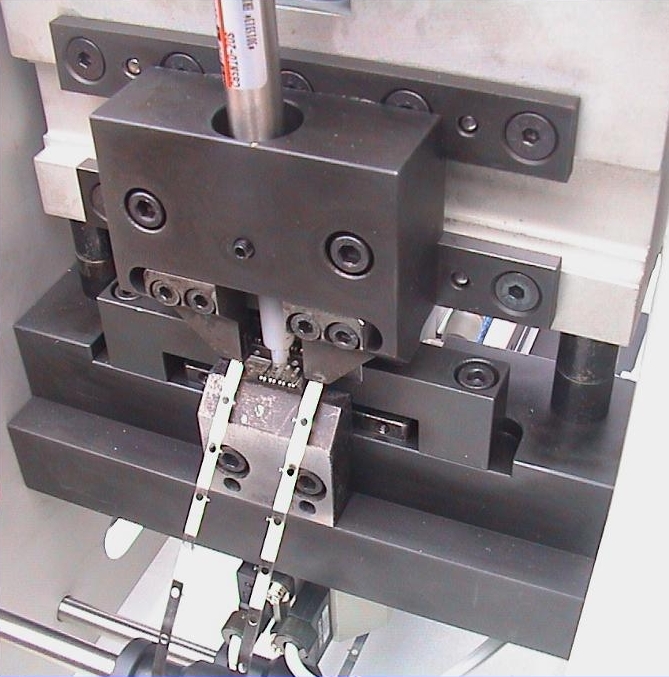

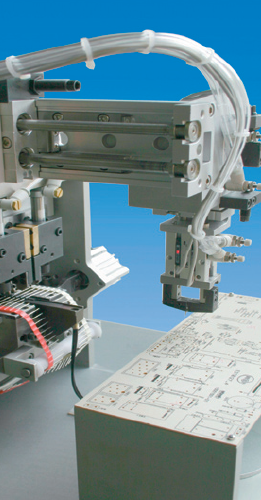

SP2006

Automatic placement machine for

through hole components

Thanks to the

experience matured with the manufacturing

of hundreds special feeders for axial and radial

components (SP21, SP22, SP26, SP27)

Olamef designed this bench placement machine for

through hole components. It is an automatic machine

designed for cutting, bending (and forming if needed)

taped axial components that will subsequently

be inserted into a PCB by the same machine’s

manipulator.

The machine can be supplied in different versions:

- It can operate as a selfstanding station with manual load and

unload of the P.C.Boards

- It can be located in line. In this case the components

are inserted into the PCB which is directly positioned on a conveyor

belt or on a load/unload system to make the operation fully

automatic. |

|

The SP2006 machine can

be customized to customer's requirement.

Beside axial and radial parts, it can be designed to place also

TO-220 transistors, ICs, connectors and other components in tube.

The

machine productivity is 1,200 parts per hour.

|

|

|

|

SP2006.01

AXIAL TAPED

COMPONENT CUTTING AND FORMING MACHINE |

|

|

|

RADIAL COMPONENTS

|

SP20

Manual pneumatic

customized machines for loose components

The SP20 line of pneumatic

machines are manually

operated equipment for individual

component feed and suitable to cut and form radial loose components.

Machine’s die assembly is designed to

per customer requirement and it simplifies and

speeds up the process by reducing the number

of steps in one single operation.

The productivity is

600 to 1000 parts per hour. |

The SP20 machine has been developed for many

applications.

Following are a few examples:

SP 20.05

|

|

|

SP 20.07

|

|

|

SP 20.08

|

|

|

|

|

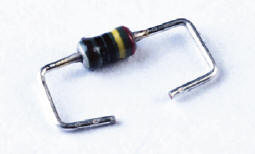

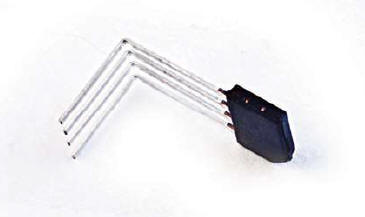

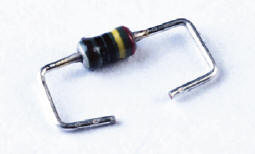

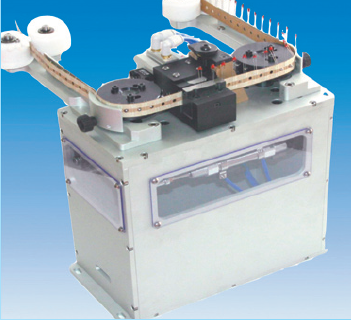

SP21

Pneumatic step by step feeder to cut and form radial

taped components

Pneumatic feeder

SP21 is designed to preform taped radial components.

Very fast system suitable to height adjustable cut or

cut and 90° bend.

This feeder can prepare components to

be picked up by a mechanical gripper.

It is suitable as working point in automatic

placement lines. |

This machine/feeder is supplied without electrical, electronic or pneumatic

systems and it is mechanically operating. Then it can be integrated to an

automatic placement system.

The productivity is 1,200

parts per hour approx.

The SP21 machine has been developed for many

applications.

Following are a few examples:

SP 21.03

STRAIGHT

CUT, ADJUSTABLE HEIGHT |

|

|

SP 21.09

CUT AND 90°

BEND |

|

|

|

|

SP21/A

Automatic step by step feeder to cut and form radial

taped components

SP21/A is a

pneumatic machine suitable to operate radial taped components.

Very fast system suitable to height adjustable cut or cut and 90°

bend.

It automatically operates components

for their subsequent ejection into a part

bin. |

The productivity is 1,200

parts per hour approx.

The SP21/A machine has been developed for many

applications.

Following are a few examples:

SP 21/A 03

STRAIGHT

CUT, ADJUSTABLE HEIGHT |

|

|

SP 21/A 09

CUT AND 90°

BEND |

|

|

|

|

|

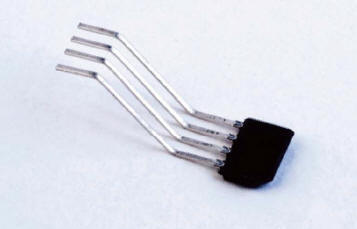

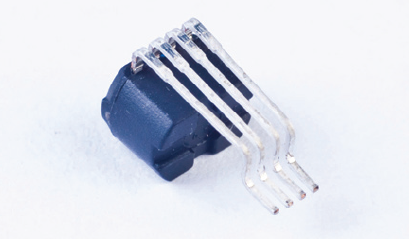

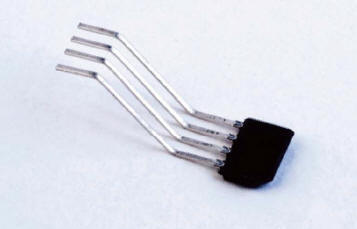

SP26

Automatic pneumatic cutting and forming machine for

taped Hall Transistors.

SP26 is an automatic,

pneumatic cut and form machine for taped Hall transistors, with tape feed and centering

positioning.

This machine

was designed to operate

Hall Transistors which are

very delicate and weak

and need perfect positioning

on the forming die.

The model SP26 is equipped

with a pneumatic centering

gripper that locks the

body of the component.

After cutting the component

from the tape, the

gripper moves it to the

subsequent step (i.e. 90°

bending, SMD form or

other forms) and finally

places it into a bin or into

a set point where a mechanical

hand (robot) can

pick it up.

The productivity is 1,200

parts per hour approx. |

The SP26 machine has been developed for many

applications.

Following are a few examples:

SP26.02

HALL TRANSISTORS CUT & FORM |

|

|

SP26.05

HALL

TRANSISTORS CUT & 90°

BEND |

|

|

SP26.06

HALL

TRANSISTORS CUT & "S" FORM |

|

|

SP26.09

HALL

TRANSISTORS CUT & "S" FORM |

|

|

SP27

Pneumatic step by step machine for taped

radial components equipped with multiple stations

SP27 pneumatic feeder is

designed to operate taped

radial components.

As this model has more

stations, it is

able to operate different

and more complex forms

depending on the customer’s

request.

It is supplied

mechanically operating,

complete with cylinders; without

electrical or pneumatic

systems and PLC.

This feeder

can prepare components to

be picked up by a mechanical

gripper. It is suitable as working station in automatic

placement lines.

The productivity is 700

parts per hour approx.

The SP27 machine has been developed for many

applications.

Following are a few examples:

SP27.01

CUT & FORM WITH KINKS |

|

|

SP27.02

CUT AND

OPEN PITCH |

|

|

SP27.04

CUT AND

90° OUTWARD

BEND |

|

|

SP27.06

90° BEND

AND INWARD BEND |

|

|

|

SP27/A

AUTOMATIC step by step machine for taped

radial components equipped with multiple stations

SP27/A is an automatic

machine designed to

operate taped radial

components.

Having more stations, it’s able to

operate different and

more complex forms

depending on the

customer’s request.

Automatically

operated components

are ejected into a

dedicated part bin.

The productivity is 700

parts per hour approx.

The SP27/A machine has been developed for many

applications.

Following are a few examples:

SP27/A 01

CUT & FORM WITH KINKS |

|

|

SP27/A 02

CUT AND

OPEN PITCH |

|

|

SP27/A 04

CUT AND

90° OUTWARD

BEND |

|

|

SP27/A 06

90° BEND

AND INWARD BEND |

|

|

|

|

SP34

Manual pneumatic

customized machines for loose components

SP34.01 is an automatic machine

designed to cut, preform and place

filters.

This machine is an example of a manipulator

that OLAMEF designed to take

radial components from the tape,

operate the leads through several cutting and forming stations and then place component

where the customer needs it.

The productivity is

approx. 1000 parts per hour.

|

SP34.01

CUT, FORM AND FILTER PLACEMENT |

|

|

Click here to see a video of this machine.

|

SP36

Loose Components Preforming Machines

The SP36 pneumatic machines are

designed for axial or radial loose components to be fed manually,

one at a time.

The machine’s die assembly is designed to quickly reach the forms

requested by the customer. It simplifies and speeds up

the performing process reducing

the number of steps to one single operation.

The

machine productivity is 700 parts per hour.

|

SP36.03

AXIAL LOOSE

COMPONENTS FORMING |

|

|

SP36.01

SPECIAL

COMPONENTS CUTTING AND FORMING |

|

|

|

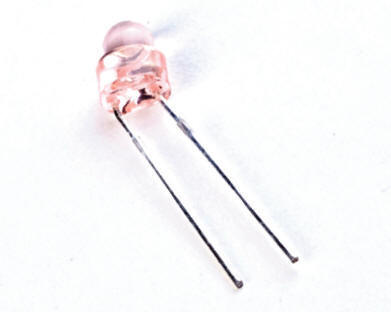

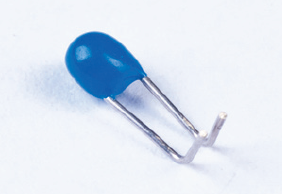

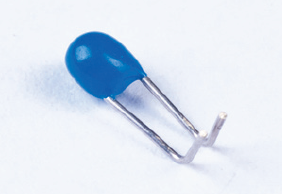

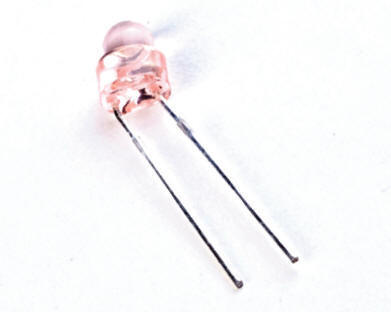

SP38

Manual machine for LOOSE L.E.D. preforming

SP38 is a pneumatic

machine, controlled by

a foot pedal.

Components

to be operated

shall be manually fed

and this tool cuts, bends

and forms loose L.E.D.s

as requested by the customer

The

machine productivity is 700 parts per hour.

|

SP38.01

LOOSE LED

CUT AND BEND TO THE LEFT |

|

|

SP38.02

LOOSE LED

CUT AND BEND TO THE RIGHT |

|

|

|

| |

|

|

Copyright ©

2001-2024

OLAMEF USA, INC.

Last Update:

06/03/2024

WEBMASTER

|

|

|

![]()