MAESTRO

3E MAESTRO

3E

8933945

Maestro 3E

now available in 600mm separation length

(Code No. 8935000)

(8931220

Discontinued model supplied with standard blades)

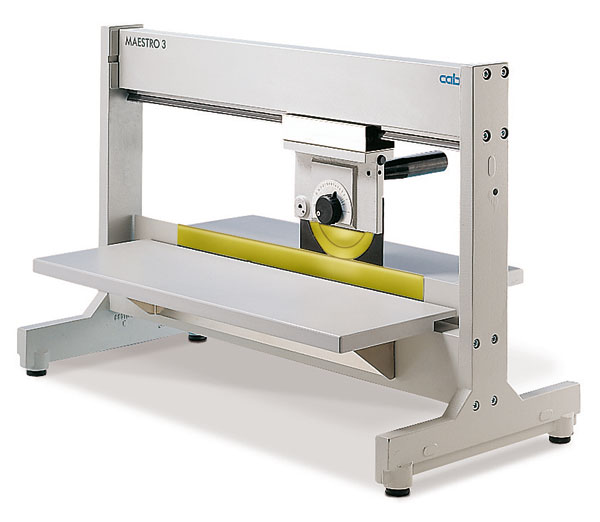

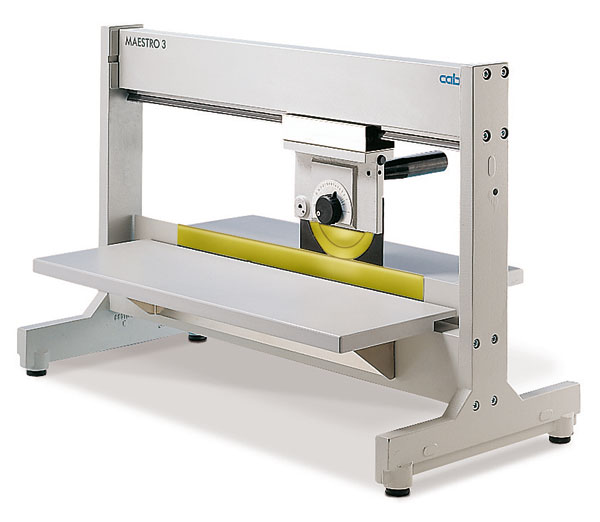

The Maestro 3

separates both small and large pre-scored PCBs. The

circular and linear blades made from a special steel ensure a

long service life. The pre-scored grooves can be

interrupted by any number of cut-outs.

The clearance between the circular blades can be precisely

adjusted with the rotary knob and is shown on the scale.

Tests have revealed that the larger the clearance between the

circular and linear blades, the smaller the stress produced

during the separation process.

During the operation, the PCB is placed with its pre-scored

groove onto the linear blade and the circular blade is then

drawn by hand across the PCB. The clearance between the

upper guide and the linear blade is adjustable to ensure that

the PCB is only separated in the pre-scored groove.

On the

Maestro 3E, the table and back rest can be adjusted with a

wrench to the best working position. The gap between the

linear blade and the unit can be adjusted to ensure that the

waste strips fall through and are sorted out.

Separation type

Component side: circular blade

Solder side: linear blade

Operation

Manual

Separation length

Max. 450 mm (17.71")

Available in 600mm

separation length (Code No. 8935000)

All the new

Maestro units come with Titanium coated blades. The following

chart shows the part numbers of the replacing blades.

top

For a list of the standard steel blades

8930501 and

8930668

click here.

Maestro 3E Specs PDF

Maestro 3E Specs PDF

|

![]()